The annual production capacity of 2 million SMT pieces and 500000 sets of BDU supporting capacity meet the BMS needs of 500000 electric vehicles and 5GWh battery systems.

PACK manufacturing uses high-quality A-grade automotive battery cells from well-known domestic and foreign battery companies such as Guoxuan High Tech and Yiwei Lithium Energy, which can meet the annual demand for 5GWh of power and energy storage systems.

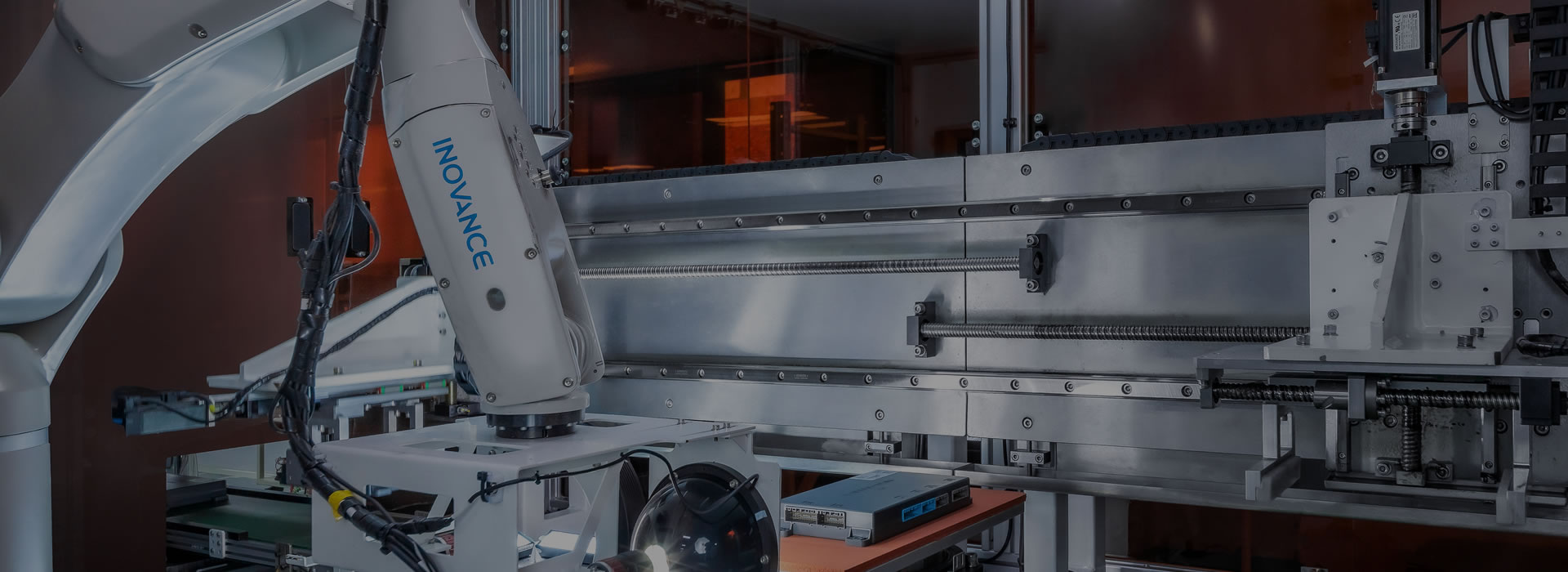

Efficient intelligent manufacturing capabilities, all key processes are digitized and automated for control. By relying on independently developed MES systems, important components of the product can be traced back to their source throughout the entire lifecycle.

Through the identification of the national integration standard of industrialization and industrialization, the provincial industrial Internet manufacturing demonstration enterprise, and the provincial digital workshop, it has repeatedly won the title of "provincial industrial Internet manufacturing integration demonstration enterprise, and provincial service-oriented manufacturing demonstration enterprise. The digital manufacturing capacity has been selected as an excellent case for promotion by the provinces and cities for many times.

Realize mass production of high-end automotive electronic SMT:High end imported SMT equipment ranks at the leading level in domestic automotive electronic SMT.

Realize full process coverage of MES system:SMT, BMS, BDU, PACK workshops all cover custom developed MES systems, and production information can be traced back.

Realize Internet based manufacturing process industry:Build an industrial Internet system, fully connect with the management information system, and won the title of Hefei Industrial Internet Demonstration Project in 2023.

Realize the first fully automated testing process in the BMS industry:BMS project ICT testing, software injection, FCT testing UV coating, PCBA board automation production.

Realize independent design and production of tooling equipment:Independently design and manufacture EOL equipment for BMS, BDU, and PACK, including testing wiring harnesses and testing fixtures.

Realize the first on load aging in the BMS industry:On load aging test simulates the quality performance of special environmental conditions.

Global Quality Management System Architecture - Built a 100000 level dust-free and clean workshop with fully automated production testing equipment based on IATF16949 and customer specific requirements.

The full process MES traceability system, digital intelligent management system, effectively controls production line equipment and personnel.

The CNAS qualification verification laboratory and testing platform, as well as a nationwide after-sales service network, have been adhering to the values of "integrity, rigor, innovation, and excellence" for many years. The company is committed to the research and development and production of new energy batteries and energy management products, with the goal of providing customers with the best products and services continuously.

Building A, Xinzhan Innovation Industrial ParkIntersection of Wenzhong Road and Huishui RoadHefei City, Anhui Province, China

+86 551-6273 5463

Building A, Xinzhan Innovation Industrial ParkIntersection of Wenzhong Road and Huishui RoadHefei City, Anhui Province, China

info@myrntec.com

COPYRIGHT © Anhui Ruineng Technology Co., Ltd. ALL RIGHTS RESERVED.

ICP Record Number:皖ICP备15018950号-2